Methyl Methacrylate (MMA): Definition, Uses, and Types

Methyl Methacrylate (MMA) is a versatile chemical compound with wide-ranging applications across numerous industries. It has various types including: adhesives, resins, and copolymers. Properties like: hydrophobicity, hardness, and weatherability make MMA valuable in modern manufacturing and engineering.

This article highlights MMA's role as a monomeric liquid that polymerizes into valuable polymers such as polymethyl methacrylate (PMMA). We delve into MMA's uses, from the production of transparent, durable plastics and coatings to its function in adhesives and medical applications.

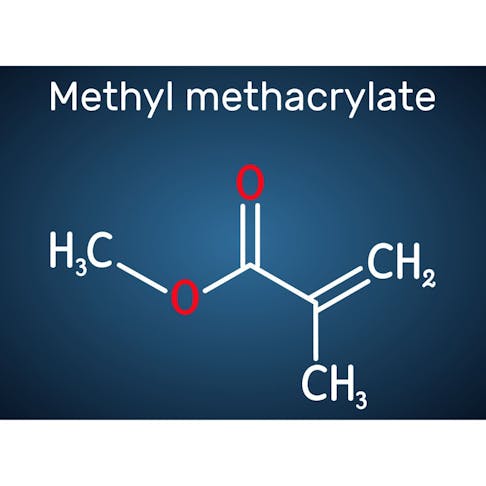

What Is Methyl Methacrylate (MMA)?

Methyl methacrylate (MMA), also known as methacrylic acid methyl ester, is an organic compound with the chemical formula C5H8O2. It is a colorless liquid with a pungent, fruity odor. It features a polymerizable methacrylate group and a reactive ester group, making it highly versatile for polymerization and copolymerization. MMA is slightly miscible with water, soluble in most organic solvents, and has relatively low volatility. It is used primarily to produce polymethyl methacrylate (PMMA), a plastic known for its clarity, durability, resistance to UV light and weathering, and its versatility as a building block in polymer chemistry. Additionally, MMA is used in making various coatings, adhesives, paints, and medical devices, due to its ability to impart properties such as: impact strength, weather resistance, and chemical resistance to the polymers it forms. MMA's ability to cure quickly also makes it valuable in the production of surgical cements and dental prostheses, for which rapid setting is required.

What Is the Common Name for Methyl Methacrylate (MMA)?

The common name for methyl methacrylate, or MMA, is the same as its chemical name, "methyl methacrylate." This monomer also goes by the name methacrylic acid methyl ester. However, MMA is best known as the main ingredient in the production of polymethyl methacrylate (PMMA) acrylic plastics, which are often referred to by brand names such as Plexiglas®, Lucite®, and Perspex®.

What Are the Chemical Properties of Methyl Methacrylate (MMA)?

The main chemical properties of MMA include:

- Has the molecular formula C5H8O2, featuring a methacrylate group with a double bond between the carbon atoms, making it highly reactive and suitable for polymerization.

- At room temperature, MMA is a colorless, clear liquid with a characteristic sharp, fruity odor.

- Has a boiling point of around 100–101 °C and a freezing point of about -48 °C, indicating its volatility and the care needed in its storage and handling.

- Is soluble in most organic solvents, such as: ethanol, acetone, and benzene, but it is only slightly soluble in water.

- The double bond in the methacrylate group is highly reactive, which makes MMA a monomer that readily forms polymers and copolymers.

- Has moderate thermal stability.

- It is considered a volatile organic compound (VOC) with potential health risks, necessitating proper safety measures during handling and use. MMA vapor can irritate the eyes, skin, and respiratory system.

How Is Methyl Methacrylate (MMA) Made?

MMA is predominantly produced through the acetone cyanohydrin (ACH) process, which starts with reacting acetone with hydrogen cyanide (HCN) in the presence of a basic catalyst to form acetone cyanohydrin. This intermediate is then converted to methacrylamide sulfate through a reaction with sulfuric acid, followed by methacrylamide's reaction with methanol, yielding MMA and ammonium sulfate byproduct.

Another method, the ethylene method, involves oxidizing ethylene to produce acetic acid, which is then reacted with formaldehyde and hydrocyanic acid to form ethylene cyanohydrin. This is catalytically converted into MMA. Additionally, the C3/C4 oxidation process represents a newer approach, in which isobutene or tert-butanol is oxidized to methacrylic acid, which is subsequently esterified with methanol to produce MMA.

The “BASF process” is another way to produce MMA, which involves four steps, beginning with the conversion of ethylene into propionaldehyde (PA) via the hydroformylation process. Following this, PA undergoes a reaction with formaldehyde, resulting in the creation of methacrolein (MA). The next phase involves the oxidation of MA into methacrylic acid (MAA). The final step in this sequence is the esterification of MAA, which leads to the production of MMA.

There's also a method involving the direct esterification of methacrylic acid with methanol. The choice among these processes depends on factors like raw material availability, cost-effectiveness, and environmental considerations, each offering distinct advantages and challenges in the production of MMA.

What Is Methyl Methacrylate (MMA) Used For?

The uses of MMA include:

- PMMA Production: Used for the production of PMMA, also known as acrylic or acrylic glass. PMMA is used in a variety of applications, including: transparent windows, skylights, aircraft canopies, and outdoor signage due to its excellent clarity and weather resistance.

- Surface Coatings: Used in the formulation of various paints and coatings that require quick drying times, durability, and UV resistance. These coatings are applied to automotive parts, marine vessels, and flooring.

- Adhesives and Sealants: A key component in the manufacturing of adhesives and sealants used in the construction and automotive industries.

- Dental and Medical Applications: Used in the medical field for manufacturing dental prostheses and bone cement. Its biocompatibility and quick-curing properties make it suitable for these sensitive applications.

- Electronic Devices: MMA's electrical insulating properties make it useful in the production of electronic components, such as LED screens and light guide panels.

Is Methyl Methacrylate (MMA) Essential in Creating Polymethyl Methacrylate?

Yes, MMA is essential in creating polymethyl methacrylate, or PMMA. MMA is the monomer that undergoes polymerization to form PMMA. This process involves the linking of numerous MMA molecules together in chains through a reaction catalyzed by heat, light, or chemical initiators. The resulting PMMA, also commonly known as acrylic, acrylic glass, Plexiglas®, Lucite®, or Perspex®, is widely used in applications ranging from optical lenses and aquariums to aircraft windows and skylights.

What Are the Different Types of Methyl Methacrylate (MMA)?

MMA serves as a foundation for a wide array of products across various industries. Listed below are the different types of MMA-based products:

1. Methyl Methacrylate Adhesives

These are high-performance adhesives known for their strong bonding capabilities, rapid curing times, and durability. MMA adhesives are widely used in the automotive, construction, and marine industries for joining materials that are difficult to bond, such as: metals, plastics, and composites.

2. Polymerized Methyl Methacrylate

This is the polymer form of MMA, commonly known as acrylic or acrylic glass (with trade names like: Plexiglas®, Lucite®, and Perspex®). PMMA’s characteristic traits are its clarity, strength, and resistance to UV light and weathering. This is why it is so suitable for use in windows, lenses, and as a glass substitute in various applications.

3. Monomeric Methyl Methacrylate

In its monomeric form, MMA is a clear, colorless liquid used as a building block for polymerization into PMMA and other copolymers. It’s also utilized as a solvent and an intermediate in organic synthesis.

4. Dental-grade Methyl Methacrylate

Specifically formulated for dental applications, dental-grade methyl methacrylate is used in the production of dental prostheses and as a component in dental cement. Its biocompatibility and ease of polymerization make it ideal for these purposes.

5. Methyl Methacrylate Resins

MMA resins find applications in coatings, inks, and adhesives, providing excellent hardness, flexibility, and resistance to abrasion and chemicals. They are often used in automotive finishes and industrial coatings.

To learn more, see our full guide on Methyl Methacrylate Resins.

6. MMA-based Copolymers

MMA is copolymerized with other monomers to produce materials with tailored properties for specific uses. These copolymers can offer improved impact resistance, flexibility, or compatibility with other materials, expanding the range of applications for MMA-derived products.

7. Modified Methyl Methacrylate Polymers

These are PMMA polymers that have been chemically modified to enhance certain properties, such as impact resistance or elasticity. Modified MMA polymers are used in applications in which standard PMMA's properties need to be fine-tuned for specific performance requirements.

How Does Polymerization Affect Methyl Methacrylate's Main Industrial Uses?

Polymerization significantly enhances the industrial utility of MMA by transforming it from a monomeric liquid into polymers and copolymers with diverse and valuable properties. Through polymerization, MMA becomes the foundation for producing PMMA, a clear, durable plastic known for its excellent optical clarity, resistance to UV light, and weatherability. This transformation allows MMA to be used in a wide range of applications, including the manufacture of shatterproof glass substitutes, lenses, and various optical devices. Furthermore, the ability of MMA to copolymerize with other monomers expands its applications into sectors such as: coatings, adhesives, paints, and sealants, in which properties like: adhesion, hardness, and resistance to chemicals are critical. The polymerization process, therefore, not only broadens the scope of MMA’s applications but also significantly contributes to the material's performance in its various end uses, making it a key material in industries ranging from construction and automotive to healthcare and electronics.

Is Methyl Methacrylate (MMA) a Plastic?

No. MMA itself is not a plastic; it is a monomeric liquid compound that serves as a building block for making plastics. When MMA undergoes polymerization, it forms polymethyl methacrylate (PMMA), which is a type of plastic known for its clear, glass-like appearance and excellent durability, weatherability, and resistance to UV light. So, while MMA is the precursor to a widely used plastic, it is not a plastic in its monomeric form.

What Are the Advantages of Methyl Methacrylate (MMA)?

Methyl methacrylate (MMA) offers several advantages that make it a valuable material in various industrial and commercial applications:

- Can be easily polymerized into polymethyl methacrylate (PMMA) and other copolymers, allowing for a wide range of applications, from transparent plastics and coatings to adhesives and sealants.

- The polymers formed from MMA, such as PMMA, are known for their excellent optical clarity and light transmission, comparable to glass but with greater impact resistance and less weight.

- MMA-based products like PMMA are durable, resistant to UV light, and maintain their properties over a wide range of temperatures.

- Polymers derived from MMA exhibit good resistance to many chemicals, making them useful in environments in which corrosion could be an issue, such as in chemical-processing equipment and medical devices.

- Used in medical and dental applications because the materials derived from it are biocompatible, making them suitable for contact with body tissues and fluids in implants and dental prostheses.

- MMA and its polymers can be easily processed and formed into various shapes, allowing for the production of complex components and designs in industries ranging from automotive to fashion.

- Compared to glass and some other plastics, PMMA offers a lightweight option without compromising on strength or clarity.

- Is recyclable, which is important in today’s environmentally conscious market. This allows for the sustainable use of materials and reduces waste.

What Are the Disadvantages of Methyl Methacrylate (MMA)?

While MMA is a valuable chemical with a wide range of applications, it does have some disadvantages that need to be considered such as:

- Is highly flammable, posing risks during storage, handling, and processing. This requires stringent safety measures to prevent fire hazards.

- Exposure to MMA vapors can irritate the eyes, skin, and respiratory system. Prolonged exposure can lead to more serious health issues, necessitating effective ventilation and protective equipment in workplaces.

- The production and polymerization processes of MMA can have significant environmental impacts, including the emission of volatile organic compounds (VOCs) into the atmosphere.

- Can spontaneously polymerize if not properly stabilized, which can be hazardous. This requires the addition of inhibitors for safe storage and handling.

Is Methyl Methacrylate (MMA) Toxic?

Yes, MMA can be toxic, particularly when exposure occurs through inhalation, skin contact, or eye contact. Inhalation of MMA vapors can lead to respiratory irritation, manifesting as coughing, wheezing, and difficulty in breathing. In severe cases, high levels of exposure may result in more significant respiratory issues. Skin contact with MMA can cause irritation, characterized by redness and itching, while eye exposure may lead to irritation and tearing. Repeated or prolonged exposure to MMA has the potential to cause more serious health concerns, including nervous system effects like: headaches, dizziness, and nausea. Although research into the long-term health effects and carcinogenic potential of MMA is ongoing, current safety guidelines emphasize the importance of minimizing exposure through adequate ventilation, protective equipment, and adherence to established exposure limits to safeguard health.

Does Methyl Methacrylate (MMA) Smell Sweet?

Yes, methyl methacrylate (MMA) is often described as having a sweet, fruity odor. However, despite its sweet smell, it's important to remember that MMA vapors can be irritating and potentially harmful, so adequate ventilation and safety precautions are necessary when handling this chemical.

Summary

This article presented methyl methacrylate, explained it, and discussed its various uses and types. To learn more about methyl methacrylate, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notices

- PLEXIGLAS® is a registered trademark of Röhm GmbH, Darmstadt, Germany.

- LUCITE® is a trademark of Lucite International, Inc.

- PERSPEX® is a trademark of Perspex International Ltd.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.